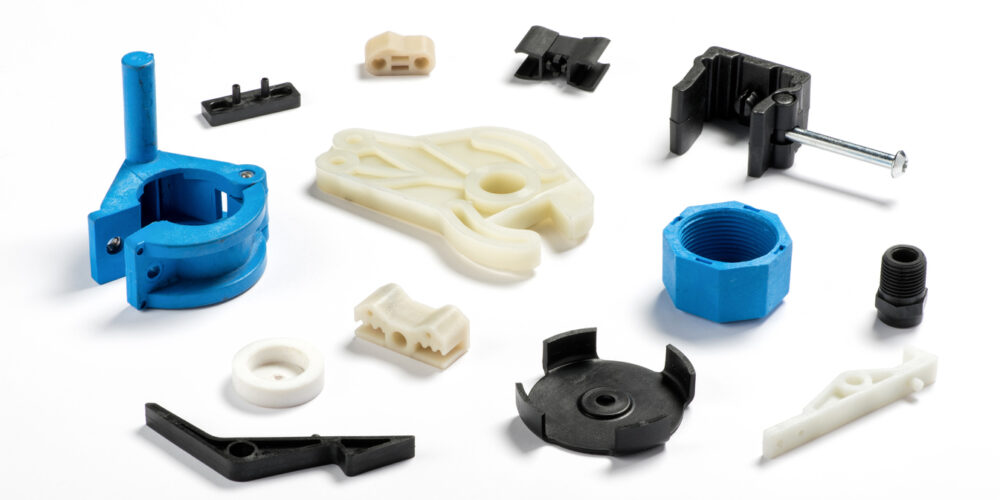

Is Rapid Prototyping Injection Molding Right for You?

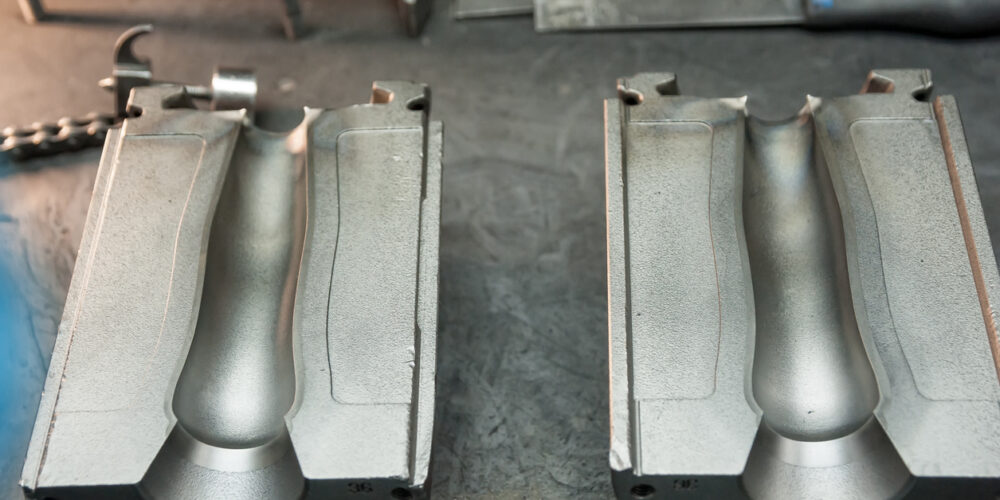

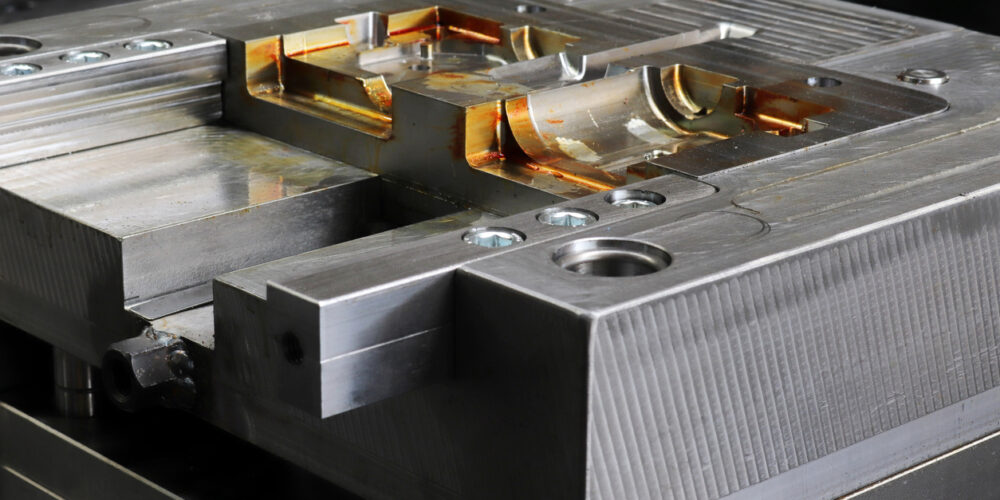

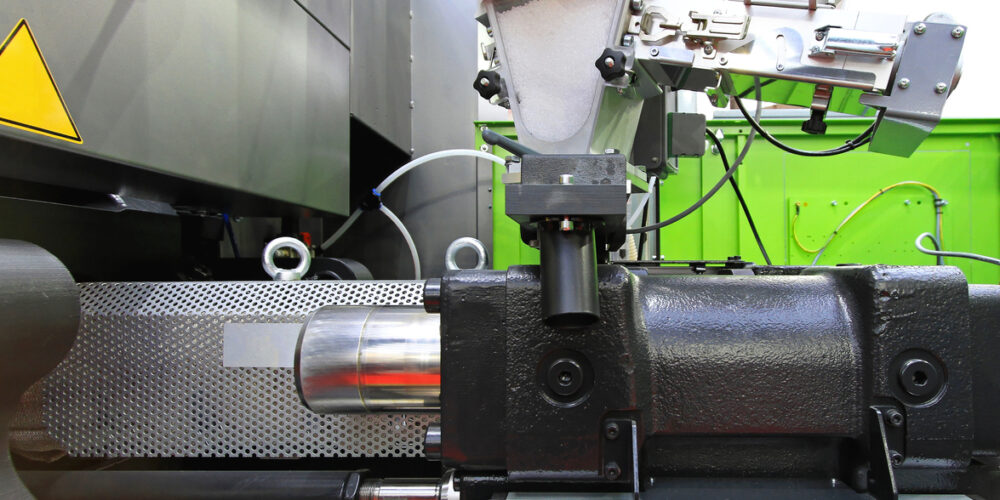

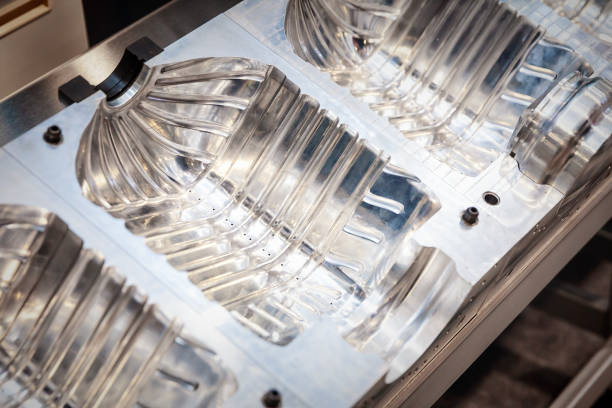

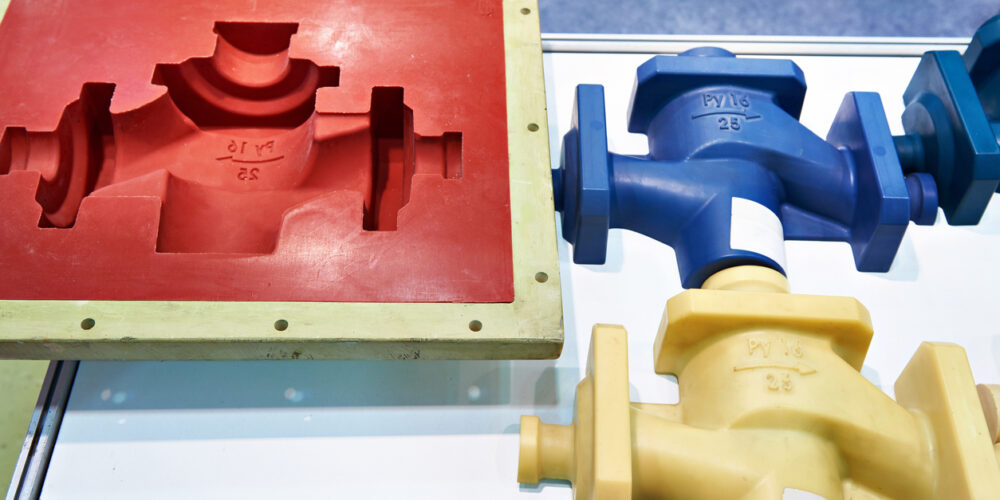

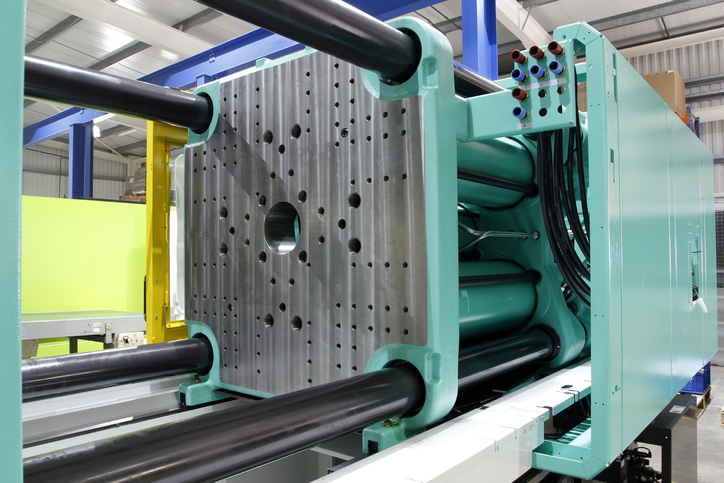

Rapid Prototyping Injection Molding Explained The rapid prototyping injection molding process uses a rapid tooling method to deliver high-quality plastic parts more quickly than regular injection molding. With rapid prototyping,…