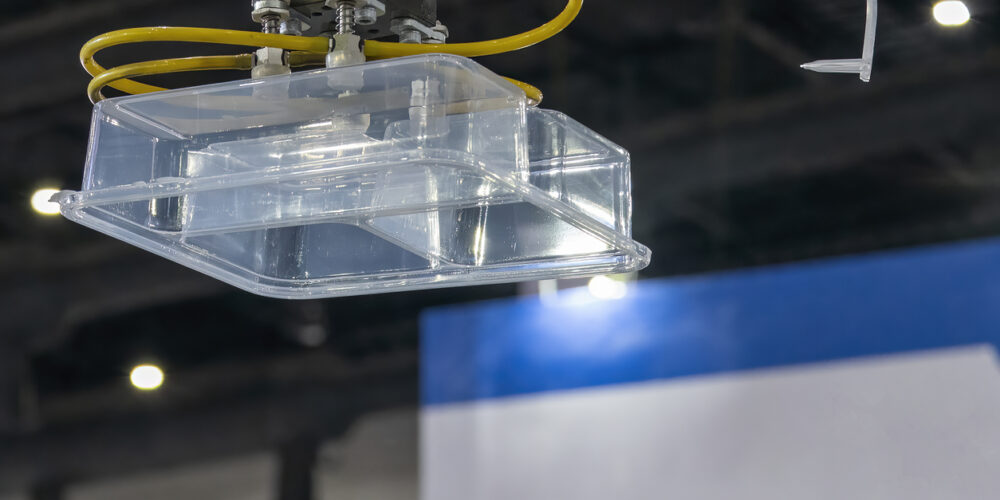

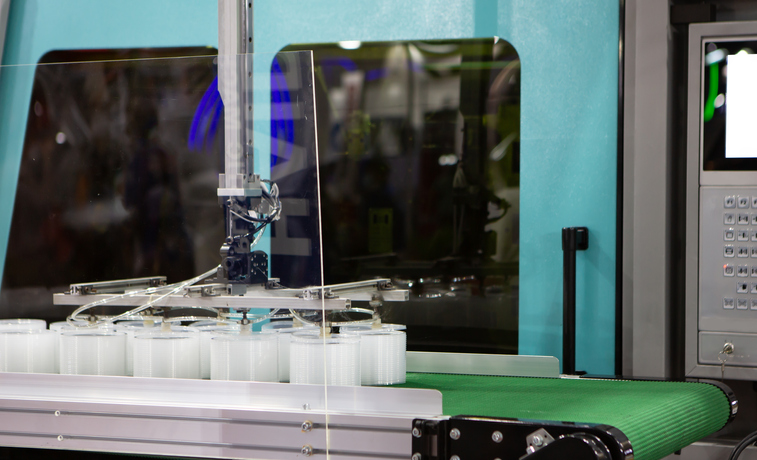

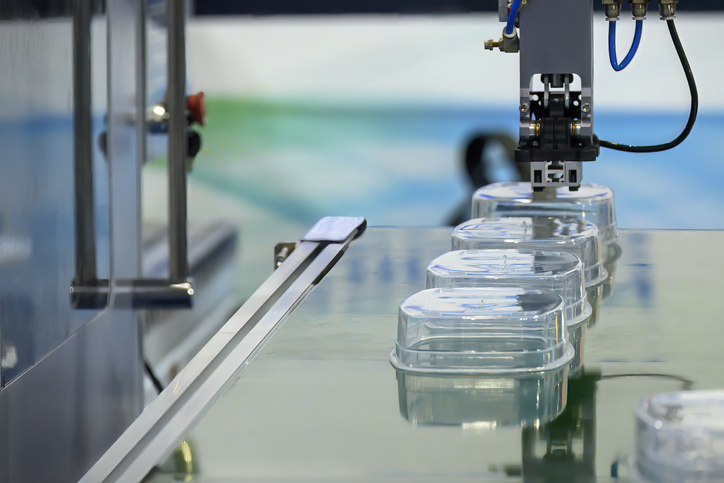

Achieve Greater Efficiency and Accuracy with Injection Molding Automation

With an increased demand for faster production cycles and higher quality standards, manufacturers are turning to injection molding automation to revolutionize their processes. Not only can automation streamline manufacturing, but…

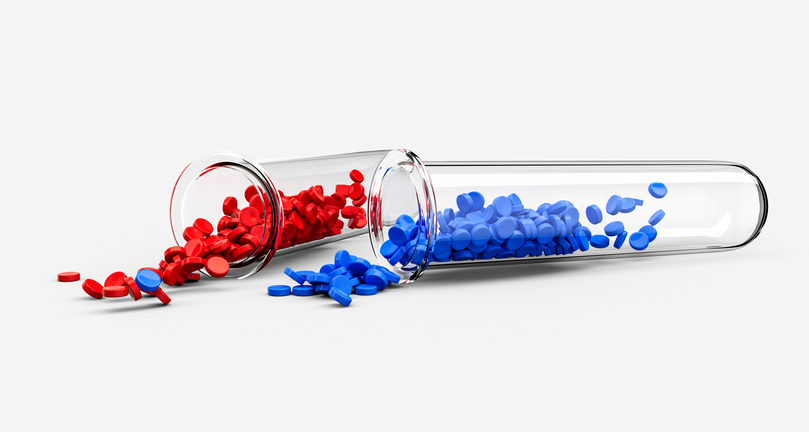

Selecting The Proper Thermoplastic For Your Product

Material selection is a critical consideration when designing or modifying a plastic component. Proper injection molding material selection impacts the manufacturing processes, quality, and the product's durability during its lifetime.…

Revolutionize the Renewable Energy Industry with Customized Plastic Parts

How Overmolding Benefits Your Product

Lower Cost, Tighter Timelines: Advantages of In-House Plastic Secondary Operations

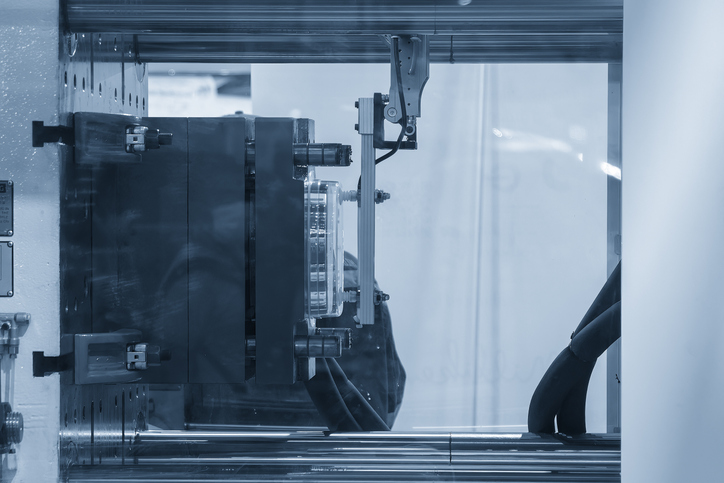

Why You Should Consider Two-Shot Molding For Your Product

Today’s consumers are not content with yesterday’s products and are always looking for upgrades or the latest product version. One manufacturing method that can elevate your product and drive new…

Optimizing Custom Molded Electrical Components

Injection molding is a vital asset across a wide range of industries due to its customization opportunities, cost-effectiveness, and efficient production. In the electronics industry, custom molded parts play a…

How In-Mold Labeling and In-Mold Decorating Benefit Your Product

In-mold labeling and decorating are methods for adding a label or graphics to a product during the injection molding process. These techniques have influenced product design for decades by elevating…

Save Time and Money with Custom Molded Electrical Components

Injection molding is a powerful asset for the electronics industry due to its ability to produce durable, lightweight products that offer enhanced electrical and heat insulation and can be customized…