A new wave of tariffs is reshaping how American manufacturers think…

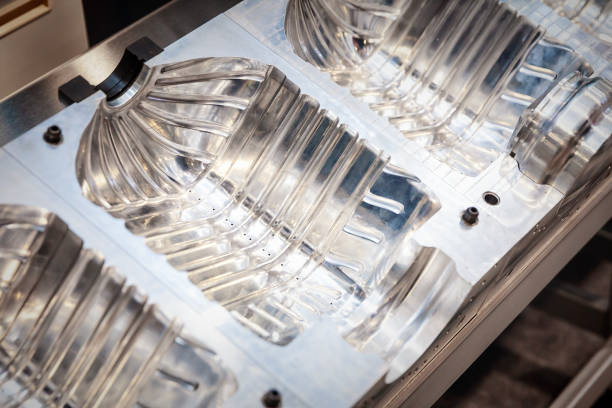

Mold Building Decisions That May Impact Cost

Producing consistently high-quality parts requires high-quality tooling (molds). Choosing the lowest-cost tooling may save you costs upfront, but in the long run, you may pay more because of broken molds and unusable parts. Unacceptable tooling may be caused by the materials used for the tooling; however, sometimes, it can be a result of how the part was designed. Where the tooling is manufactured can also impact costs. Consider these factors during the mold building process.

Product Design

Product design has an impact on tooling costs and time. Complex molds take more time to build and can add additional costs during the injection molding process. Complex product designs, such as those with undercuts or holes, may require side actions with cams or lifters. Undercut features are perpendicular to the main parting line and can not be produced with a straight-pull mold. Think of a square with indentations on the sides. The part of the tooling creating the indents would prevent it from being removed with regular tooling. Side actions are inserted and allow material to flow around them to form the undercut feature and then are removed before the mold is released. These should only be used when the design cannot be simplified to avoid them because they can add significant costs.

Part Size and Cavitation

The part size will impact tooling. Large parts will need to be in a stand-alone mold. Low to medium volume small parts with only minor variations between them may be produced using interchangeable mold inserts, which can save money. However, independent molds may be a better option if they are high-volume parts.

Cavitation should be considered carefully. Each cavitation increases tooling costs. However, high annual volumes may more than make up the additional upfront costs as a result of lower piece part price.

Mold Materials and Mold Class

A clear project scope will help the mold builder decide what the tooling should be made from. There are several common grades of metals that are used to build molds, including aluminum, soft and semi-hardened steel, and hardened steel. The material used may depend on the product development stage and validation, the part size, the number of cavities, and the number of shots the mold is expected to produce.

Aluminum is a soft metal and may be used for pre-production prototype parts or low-volume parts. It can be machined twice as fast as hardened steel and doesn’t require heat treatment, which will lower costs. However, it also wears out much faster than steel, delivering 10,000 shots or less. Larger products may not mold well in aluminum tooling because the softer aluminum isn’t suitable for high clamping pressures. Additionally, aluminum may not work with advanced resins or those with additives that may scratch the mold.

Soft and Semi-hardened steel is harder than aluminum and has a tool life of 50,000 to 100,000 shots, depending on part material and design. These metals also do not require heat treatment. Although they are not machined as quickly as aluminum, they can be machined faster than hardened steel.

High production parts require hardened steel tooling. The upfront tooling costs are higher, and the manufacturing time is longer, but this can be made up for in reduced part unit costs and longevity of the molds, which can get 1 million or more shots.

The injection mold SPI class, defined by Plastics Industry Association, standardizes the physical tool construction and the mold’s life expectancy. The mold classes range from Class 101, the most robust, through Class 105, intended for prototype parts only. Selecting the appropriate class will prevent over-engineering, which can drive up costs.

Type of Mold

Molds are classified as hot runner or cold runner molds, and their use will depend on part geometry, expected part quality, and volume requirements. The runner is the channel in the mold where the molten plastic flows from the machine barrel to the cavity.

In a hot runner, the channel is heated, and the plastic remains molten, so it is not attached to the part. In a cold runner, the plastic solidifies along with the part. In a two-plate injection mold, an additional step is required to remove the runner from the part. In a three-plate mold, the runner separates from the part when the mold opens.

Although hot runners have reduced cycle time, lower part manufacturing costs, and high-quality parts, the molds are more expensive to manufacture and maintain. Cold runners have less expensive molds, and changing materials and colors for the parts are easier.

Manufacturing Location

The more hands that touch your molds, the higher the costs. The location of the mold manufacturer can impact how long it takes to get your mold and the shipping costs. If your mold is being made overseas, shipping and handling expenses should be factored into your total costs. Consider working with a molder that has an in-house tool shop. This not only expedites getting into production, but it can also save you time and money when maintenance and repairs are needed.

Deluxe Plastics Brings 75+ Years of Experience to Its Mold Building

Backed by more than 75 years of experience, we are a full-service injection molding company. For your mold building needs, we have both in-house mold building and overseas facilities to ensure you have the most cost-effective options available to you. Our experienced team will machine your mold during its creation and perform maintenance and repairs to ensure long-lasting performance.

Contact us to learn more.