A new wave of tariffs is reshaping how American manufacturers think…

How Our Vietnam Facility Provides Cost-Saving Options

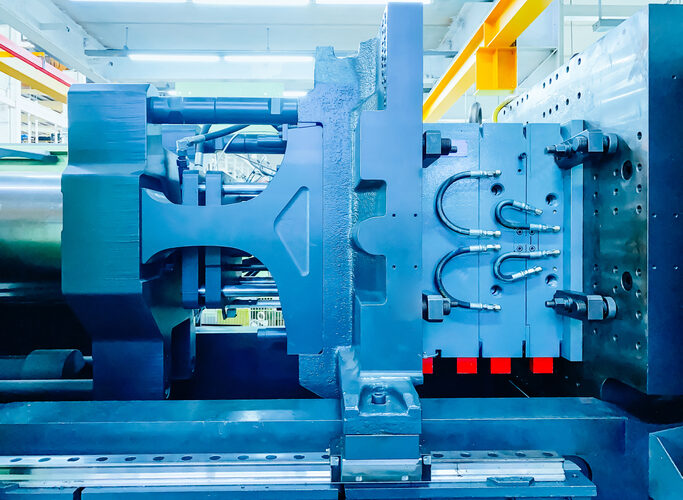

Providing Quality, Cost-Effective Injection Molding from Our Vietnam Facility

In addition to our U.S. locations, we also have an overseas injection molding facility to best serve our customers. Our Vietnam injection molding facility allows us to provide cost-competitive options to our clients. Injection molding, assembly, and secondary operations are done with speed and the quality-first attitude seen across our entire organization.

In recent years, Vietnam has become a formidable competitor to Chinese manufacturing, offering valuable benefits. The country has seen explosive growth, with exports to the U.S. surging, supported by a heavy national investment in infrastructure, a stable political system, free trade agreements, and a dynamic workforce.

Capabilities

Since the facility opened in 2012, it has grown to 250 employees, three assembly lines, and seven injection molding machines ranging from 140 US tons to 500 US tons. We can mold parts from small gears up to a 12in x 12in x 12in part.

In addition, secondary operations, such as pad printing, sonic welding, and labeling, are expertly executed by trained and attentive staff. We have a close relationship with a Vietnamese vendor for PCBs, but we have an electrical engineer on staff and a team to assemble electronic mechanisms.

Shipping to the U.S.

Many businesses in the U.S. have seen issues with labor shortages creating bottlenecks, leading to difficulty getting parts. One of the benefits of working in Vietnam is greater access to labor, allowing us to turn around large orders quickly. We have two to four containers of parts shipped to the States every month, so shipping is cost competitive, as well. Plus, tariffs for Vietnam are much lower than China.

Small mechanisms ship well, with eight thousand fitting on a container. Larger injection molded pieces sometimes don’t fit as tightly, so you are shipping more air. So, some customers may choose to have mechanisms made in Vietnam and have housing molded in one of our U.S. facilities.

High-Quality Workmanship

When some people think of overseas work, they immediately worry about the quality and if communication will impact it. Our Vietnam facility is U.S.-run and ISO 9001:2015 certified, so stringent quality standards are upheld. Management speaks English and Vietnamese, so there are no language barriers between us and our customers and management and employees. The components you get from our Vietnam facility will always meet your requirements.

Look to Deluxe Plastics

If you are looking to pull your work from China but want the cost savings from manufacturing abroad with the ease and expertise of an American company, look no further than Deluxe Plastics. When you work with us, you’ll receive high-quality, streamlined production from a talented team who will provide outstanding support and customer service.