As sustainability continues to shape the future of manufacturing, procurement professionals…

Tight Tolerances in the Small Appliance Market

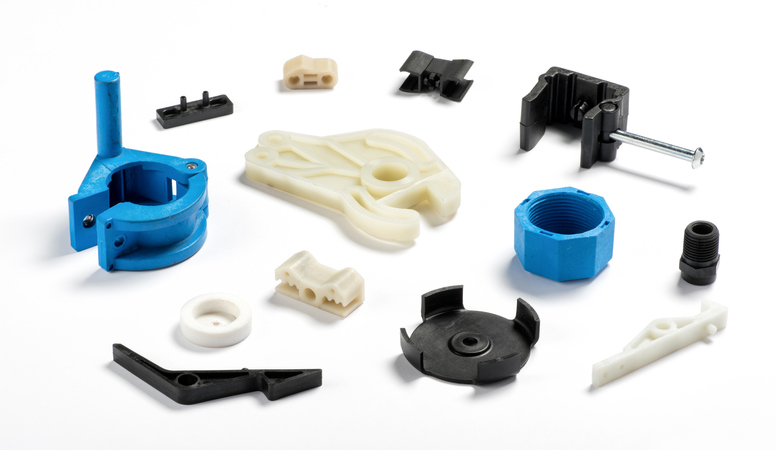

Functional assemblies and multipart products must be manufactured to work well together. Dimensions on these components must be specified for manufacturing so that they fit and function as intended when produced. Certain components have less leeway with critical dimensions. Plastic injection molded components of small appliances such as mechanical parts, gears, and switch housing found in blenders, coffee makers, toasters, and juicers often require tight tolerances to function properly.

Understanding Tolerance

To understand tolerances, you must first understand accuracy and precision. Accuracy refers to the closeness of a measured value to the actual value. Precision refers to the repeatability of getting that result. Accuracy and precision are independent. You can have a highly accurate part but not be able to reproduce it consistently, or you may be able to reproduce a part with dimensions that are off by the exact same amount each time.

Of course, the goal is to have a level of accuracy and precision that allows your product to function properly. This is where tolerance comes in. Tolerance tells your injection molder how much leeway you can allow in a particular dimension. Each dimension on a drawing is provided with a minimum and maximum level. Tolerance is the difference between the minimum and maximum levels.

Tight tolerances are usually required for complex or critical parts. The small appliance may not work if the tight tolerance is not met. For example, small appliance parts that can’t tolerate variation in flatness, like gears or parts that must seamlessly join to prevent leaking. These types of components need a tight tolerance for functionality or aesthetics. For these parts, tight tolerance means fewer rejects and failures, and problems with mating during assembly can be avoided. In the long run, achieving the tolerances required for your part saves you time and money. However, costs increase as tolerances decrease because additional processing may be needed. So, it is essential that the need for tight tolerance is considered carefully.

What Impacts Tolerance?

Part complexity, material, manufacturing processes, and tooling all impact the tolerances that can be achieved. If a tight tolerance is required, it should be considered early in the design process. Work closely with your injection molder to ensure your tolerances can be met.

The resin selection is key when dealing with tight tolerance parts. The rates at which resins shrink, warp, and expand vary. All materials shrink during the cooling process; however, some shrink more than others. Amorphous materials typically shrink less than crystalline materials, which can help hold tight tolerances. Shrinkage is predictable and should be accounted for in the design stage.

Polymer chains in amorphous materials are randomly oriented and remain that way when cooled, resulting in shrinkage in the same direction. In crystalline materials, the polymers chain coil up into what are called crystals and orient in the direction of the material flow, resulting in shrinkage in the direction against the flow being higher than in the flow direction.

Part geometry and complexity can impact how tight the tolerance can be. Walls that are too thick or vary in thickness may warp. Part size may impact tolerances as well. It is harder to hold a tight tolerance on a larger part. Challenges may be compounded by the material choice, which is another reason to work closely with your injection molder early in the design phase.

Another key to manufacturing tight-tolerance parts is using consistent processes. Certain process conditions can impact tolerances more than others. For example, quick cavity filling and uniform cooling can help to create consistency and achieve tight tolerances. Noticing when parts start to go out of tolerance and immediately fixing the issue is also critical.

Finally, the mold design is critical but is dependent on other factors. The mold must be built larger to account for the shrinkage of the material. A well-designed mold that offers consistent, repeatable heating and cooling between shots will allow you to maintain tighter tolerances. Larger or complex parts may require more than one gate to avoid uneven fills and unexpected shrinking and warping.

Work with an Experienced Partner

Working with an experienced plastic injection molding partner early in the design stage will ensure the repeatability of tight-tolerance parts. Our team at Deluxe Plastics has longstanding expertise and background in material selection, and we can work closely with small appliance customers that require tight tolerances to assist in material selection. We establish our molding processes using scientific molding principles, which look at each molding phase to optimize our process and ensure consistency.

When tooling is being built, we will ensure dimensions are created “steel safe,” which means that, if needed, steel can simply be removed after tool creation instead of welding or inserting areas that can be costly. To ensure tolerance is maintained, we often use vision systems, CMMs, or functional / go + no-go gauges.