At Deluxe Plastics, We’re All Responsible for Quality Management

No matter the team member or place in the organization, we each play a role in ensuring that every project meets the standards expected within and outside our company. It is with this in mind that we developed a Quality Management System to direct our continuous improvement efforts.

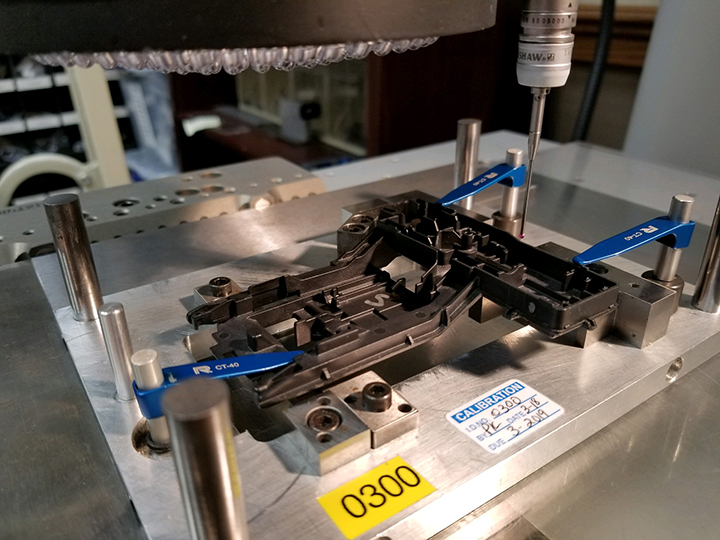

This strong core belief about our business enforces our commitment to meeting customer requirements. We do that by always seeking improvement to our products, services, and the way we interact with customers to deliver the performance and parts they need. Our Quality Management System is essential to this mission and is powered by standards, tooling, and measurement processes that guide our improvement efforts.

As a full-service, Wisconsin-based injection molding and engineering company, Deluxe Plastics empowers your plastic manufacturing at every stage of production. Many of our services revolve around our extensive injection molding capabilities, complete with 55 injection molding machines in varying tonnages. A fully-staffed engineering team heads up our efforts in part design — where we collaborate with you to develop the right solutions. With more than 75 years of combined experience, our mold building and design team has the expertise to create — and maintain — molds for long-term usage and high performance.

Our Quality Management System is there to back up and validate the results of all our offerings. We never stop striving to find ways to improve our processes or deliver better results for our customers and have a proven methodology to ensure we continue to build on our long-lasting commitment to those we work with.

Feel free to connect with our team at any time. If you’re ready to take the next step with Deluxe Plastics, request a quote or more information here.

Experience Unmatched Quality with Deluxe Plastics

At Deluxe Plastics, we take pride in the quality of our products. Our Quality Management System allows us to create the best possible plastic products for a variety of industries. With four turnkey manufacturing locations, we can help you from start to finish — from part design to mold building to injection molding and secondary services. We can also deliver quality sustainable engineering support to help you meet your sustainability goals with premium molded products.

Quality Management System Essentials

- SPC Monitoring

- Optical Comparator

- Moisture Analyzer Capability

- Full PPAP/FAIR Submission

- Beginning to end Product and Lot Traceability

- Micro-Vu Vertex Vision System with Integrated CMM function

- ISO 9001:2015 Certified