A new wave of tariffs is reshaping how American manufacturers think…

Why You Should Consider Two-Shot Molding For Your Product

Today’s consumers are not content with yesterday’s products and are always looking for upgrades or the latest product version. One manufacturing method that can elevate your product and drive new sales by meeting consumer desires is two-shot molding. Even industrial products can reap the benefits. Below, we will dive into two-shot molding, explaining what it is and how it may benefit your products.

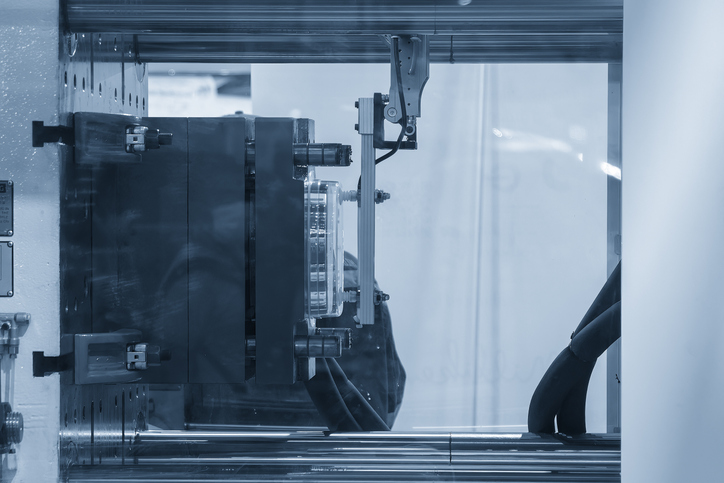

What is Two-Shot Molding

Two-shot molding is often referred to by other names (dual-shot, multi-shot, or double-shot), which can be confusing. To make matters even more confusing, engineers can have differing opinions on what it means, such as using two barrels with different colors, molding a part and then transferring it to another mold to overmold it with another resin, or performing multiple shots of the same resin to build up layers. Here we are referring to a process that uses one injection molding machine and mold to create a cohesive part using multiple color resins or multiple resin types.

This two-step process molds one plastic on top of another. It starts like a typical injection molded part, with the first resin being injected into a mold and cooled to form a solid part. This is done on one side of the mold. The mold then opens, rotates 180 degrees, closes, and the second shot is injected over and/or around the first shot, creating a tight bond between the two materials. Simultaneously, the first shot is injected into the other side of the mold, repeating the process.

Another method for two-shot molding is transfer molding. The final outcome is similar to the two-shot rotational molding, but the process is slightly different. The substrate is molded on one side of the tool and the part is transferred to the other side of the tool to have the next part molded.

The plastics used can be different colors or different hardness. The latter is often used for creating a soft grip on tools and knobs.

Benefits of Two-Shot Molding

Without two-shot molding, manufacturing a product made from different plastics or plastic colors would require additional steps. One option is to assemble the parts with adhesives or fasteners. However, this increases assembly time and may affect the durability and aesthetics of the product. For products that want different textures or graphic elements, pad printing or silk screening can be used, but they add additional production steps and costs and won’t be as durable as a two-shot molded product.

While the two-shot process is more complicated than single-shot molding, there are several advantages that can make it worth your while.

- Offers a variety of interesting product design and branding opportunities.

- Strong bonding increases functionality and durability.

- Secondary operations are eliminated, reducing costs.

- Repeatability and precision are increased.

- Scrap is reduced because trimming parts isn’t required to join them.

Overall, the advantages of two-shot molding include reduced production and assembly times, the ability to create complex and creative designs, and reduced part costs.

Uses for Two-Shot Molding

Products used for two-shot molding are seen across industries, including appliances, automotive, industrial, medical, toys, and more. Here are a few examples of how two-shot molding can improve a product.

- Integrating soft, non-slip textures with clear markings on appliance knobs and dials create an enhanced user experience and readability.

- Implementing decorative accents with different colors or textures can enhance the aesthetics of an appliance.

- Automotive interior components, such as knobs, switches, and dashboards, can be integrated with seals and soft-touch surfaces.

- When hard plastic is molded first and rubber material second, a soft grip can be created to improve user experience.

- Two-shot handles provide ergonomic benefits and shock absorption for tools.

- Respiratory masks can be ridged with a soft seal that touches the face for improved comfort.

- Medical syringes can be made with soft plungers for smooth operation to improve patient comfort.

- Living hinges for caps and lids can be created.

- There is no risk of toys coming apart or small parts, like screws, coming off and causing a choking hazard.

- Toy figures can be made from different materials, or dolls can be made with realistic skin tones and hair textures.

Overall, two-shot molding offers a flexible and efficient way to produce complex, multi-functional products across various industries. By combining different materials in a single piece, it enhances product performance, comfort, and aesthetics while streamlining manufacturing processes.

Contact Deluxe for Expert Two-Shot Molding

Ready to level up your project with quality injection molding? Contact Deluxe today.