A new wave of tariffs is reshaping how American manufacturers think…

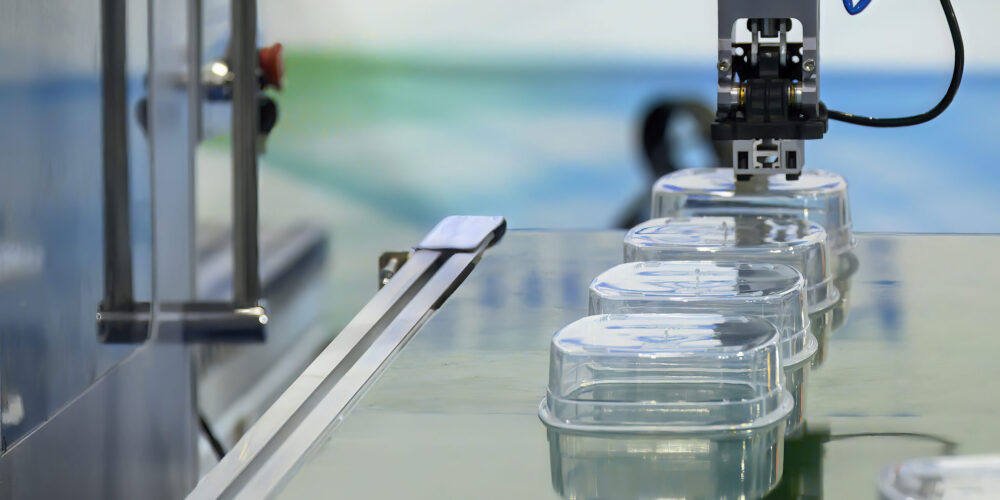

Reshoring Plastic Injection Molding: Advantages and Opportunities

Bringing Manufacturing To The USA

In recent years, reshoring has gained significant traction across various industries, and plastic injection molding is no exception. Offshore manufacturing saw its heyday decades ago when manufacturers moved production to countries that paid low ages and had looser environmental regulations. For many, the cost advantages, in terms of money and customer demands, have eroded, resulting in companies looking to bring manufacturing closer to their customer base. Reshoring plastic injection molding offers numerous benefits not only to businesses but also to their customers. In this blog post, we will explore the reasons why reshoring plastic injection molding is a strategic move that can positively impact your operations and bottom line.

Why Reshore?

There are several compelling reasons to reshore contract injection molding to the USA. However, the decision to reshore should be carefully considered by evaluating the total landed costs, considering duty, freight charges, and unquantifiable costs like customer satisfaction and trust. There are times when relying on overseas manufacturing makes sense. In these cases, working with a partner with domestic and international facilities can provide the best of both worlds and additional cost-saving options.

However, for many, reshoring can provide several tangible benefits that can enhance business operations. Below, we discuss key reasons reshoring is a practical strategy, touching on areas such as operational control, lead times, economic impact, environmental sustainability, customer experience, and innovation.

Maintaining Operational Control

One of the most prominent advantages of reshoring is it allows businesses to have better control over their manufacturing processes. When production is outsourced to distant locations, it becomes challenging to maintain the same level of oversight and quality assurance. By bringing operations to a domestic partner, companies are closer to the injection molder for collaboration, or if issues arise that would better be resolved in person.

Get Products Faster

Additionally, reshoring results in significantly reduced lead times. When production is conducted overseas, shipping and customs delays are often inevitable, leading to longer wait times for products or components, which trickles downstream to your customers. By manufacturing locally, businesses can expedite delivery processes by removing the risks associated with international shipping and customs activities, ensuring that orders are received promptly without unnecessary delays.

Some companies may compensate for these delays by warehousing extra products or components. However, this has associated costs—space, overhead, inventory management, obsolescence, etc.—that should be considered.

Environmental Considerations

In addition to the economic advantages, reshoring has a positive impact on the environment. Manufacturing overseas often involves long-distance transportation, which contributes to carbon emissions and environmental degradation. By producing closer to home, companies can reduce their carbon footprint and minimize the environmental impact of their operations. This aligns with a dedication to sustainability and environmental stewardship, values that are essential to business and consumers.

Enhancing Customer Experience

One of the most significant advantages of reshoring is the enhanced customer experience it facilitates. When production is closer to home, communication becomes more efficient and effective. Customers can easily reach out with their requirements, and businesses can respond promptly to any inquiries or concerns. This proximity fosters a stronger relationship between companies and their customers, ensuring that needs are met with precision and care.

Broader Economic Benefits

A rarely discussed but critical benefit of reshoring to a domestic manufacturing partner is the preservation and growth of specialized skills and trades within your community. By partnering with domestic manufacturers, companies contribute to sustaining a workforce skilled in advanced manufacturing techniques. This creates a stronger talent pipeline, ensures the availability of local expertise, and reduces the risk of a skills gap over time. It also fosters innovation within the industry as skilled professionals collaborate and advance processes, benefiting not only one company but the entire sector. This also contributes to the growth of the domestic economy as the employees spend locally.

Reshoring Injection Molding With Deluxe Plastics

If you have injection molding projects offshore and are considering bringing them stateside, give us a call. We will evaluate it and help you determine the best course of action. With extensive experience with onshoring programs, you can expect a smooth transition. Because we have several facilities that offer a wide range of services, including engineering support, tooling, molding, secondary operations, metal stamping, assembly, and more, we have the expertise to deliver everything you need.