A new wave of tariffs is reshaping how American manufacturers think…

Lower Cost, Tighter Timelines: Advantages of In-House Plastic Secondary Operations

Custom plastic parts require more than just injection molding to be considered ready for market. Strategic plastic secondary operations services like assembly, painting, and even inventory management are vital steps that ensure your product is completed to your precise requirements and prepared for final installation. Each stage is critical to ensure that your part is made to the highest quality standards and completed within the budget and timeline you require.

Without the right partner, you risk extending the production timeline for your project or ramping up the additional costs that come with seeking multiple manufacturing partners to complete each stage. When you partner with an injection molder who can handle these services in-house at every stage, you save time and money and ensure that your products are backed by rigid quality standards. You can also begin to develop long-term relationships with quality manufacturers that you can count on to serve your needs for many projects to come.

Read on to explore the benefits of in-house plastic secondary operations and why Deluxe is the ideal partner for your project from start to finish.

The Benefits of In-House Plastic Secondary Operations

Fast Time to Market

Plastic secondary operations are necessary for many projects, but if you must turn to two manufacturers — one for the design and molding of your product, and one for the assembly, painting, or inventory management — this adds time to production. There will be a delay in how quickly you can complete your project and get it into the hands of an end user, which can stall your growth and prevent you from gaining a competitive advantage.

In-house finishing services help speed up the process because you can avoid needing to find a second manufacturer to partner with and transport your products from one to the next. This time-saving can have a critical impact on your ability to finalize your project and get it to market without delay.

Cost Effective

In-house plastic secondary operations are often more cost-effective than the alternatives, helping protect your bottom line and your interest. If you choose to go an alternative route, you may be forced to find an additional production partner to work with to complete the steps you require. There are a range of costs that come with this choice, including the time and money it takes to find a new manufacturer and the time and money it takes to transport your products from one partner to the next.

Building out the means to complete assembly, painting, or inventory management within your own organization is also costly due to the extensive machinery and skills necessary to complete the job. For many businesses, building out the necessary segments to support secondary services in-house means shifting funds and focus away from other critical efforts.

Partnering with the right molder will prepare your project for success and help you shave costs during the production process while still enjoying a high-quality completed product. They can also help you find additional ways to save so you can manage your injection molding costs without compromising quality.

Flexible

The secondary services that your products require may differ from project to project. While one project may require unique hardware, insertion, or assembly services, another may need only painting or inventory management. As your needs shift, choosing a long-term manufacturing partner with the capabilities to support you is important.

When you form a long-lasting relationship with a molder that offers a range of in-house plastic secondary operations, you can ensure that your needs will be met at every stage of every project. Whether you require a wide array of services to finish your project, such as assembly, custom labeling, and inventory management, or you need only one supportive service to meet your needs, the right partner can help.

Designed for Excellence at Every Stage

When you partner with a molder equipped to handle the secondary services required to complete your project, you can count on their expertise to achieve smarter design for your product from the start. A molder with a deep understanding of the various disciplines involved in turnkey molding — from design and molding to assembly and painting — will understand some of the design difficulties that are inherent in these processes and can design around them. For example, if your custom part requires painting, the right molding partner will account for these needs to facilitate a better process and result, as opposed to a partner who will only factor in molding within their design.

When you choose an injection molder that considers both molding and finishing services within their design, you can achieve better results and mitigate challenges that might otherwise arise. This keeps your project on time and within your budget and ensures it’s made to the highest quality.

Partner with Deluxe for Leading Plastic Secondary Operations

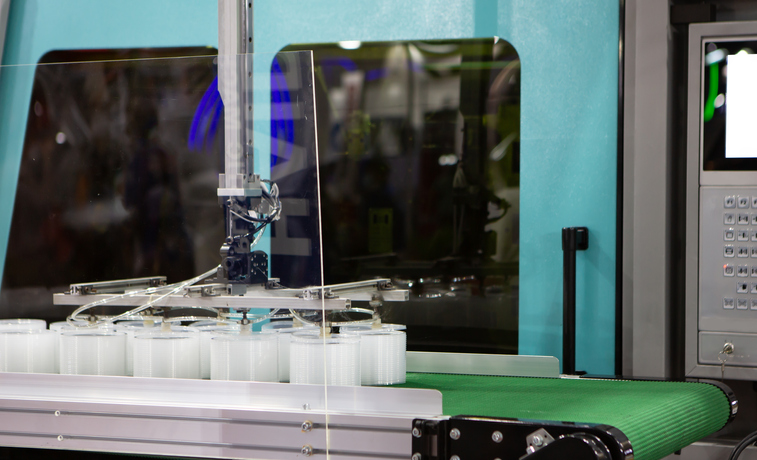

At Deluxe, we’re committed to achieving the highest quality results in every project we support, and we’re here to serve your needs from start to finish. We offer a full-service approach to plastic injection molding, from initial design guidance and prototyping to injection molding and mold building. We also offer an extensive range of in-house secondary services, including hardware, insertion, assembly, engraving, labeling, custom, packaging, and even inventory management. These services allow us to support the needs of our customers from start to finish and tackle high-volume projects that require secondary operations with ease.

For decades, we have delivered exceptional injection molding and secondary services to an array of industries in need, from the industrial sector to the medical industry, commercial goods, and more. Our expertise has been honed from the variety of projects we’ve taken on, and we have a deep understanding of how to transform a complex concept into a fully finished part that means the highest standards of quality.

We have three facilities within Wisconsin and one overseas, and these advanced spaces are filled with the leading technology and expert teams necessary to handle your project needs. Our award-winning team, sustainable engineering approach and ability to handle high-volume projects help us stand out from the competition in the value that we produce for our customers.

Ready to learn more about how our full-service engineering approach can serve your part needs? Get in touch with us today to explore your project needs and level up your finished product with our plastic secondary operations.