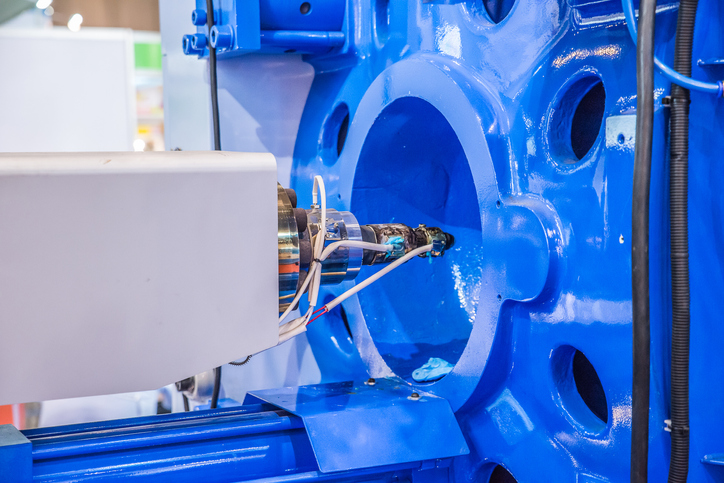

Save Time and Money with Custom Molded Electrical Components

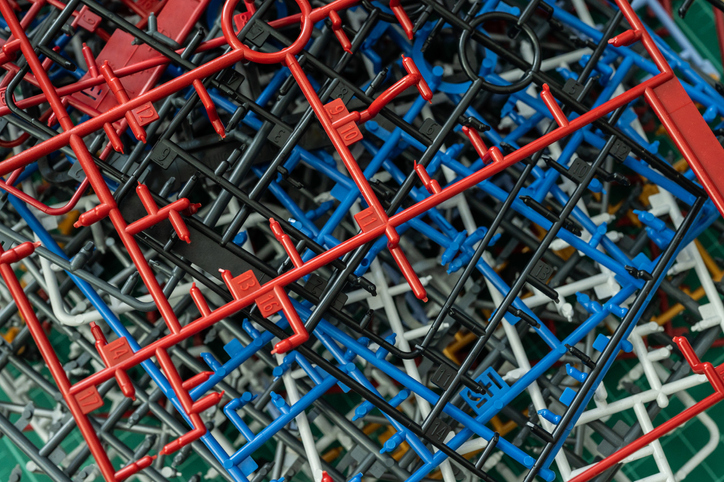

Injection molding is a powerful asset for the electronics industry due to its ability to produce durable, lightweight products that offer enhanced electrical and heat insulation and can be customized…