Whether you are a production manager, operations executive, or other company…

5 Ways to Reduce Your Injection Molding Cost

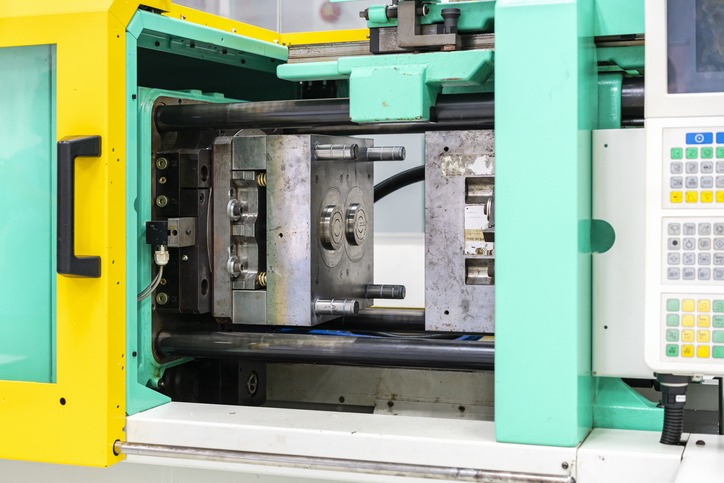

Reducing injection molding costs is a top priority for many companies, and your savings shouldn’t have to come at the expense of your molded part’s quality. When you partner with the right injection molder, you can cut down your injection molding cost without sacrificing the quality and functionality of your part.

We’ve gathered our top five ways to lower your injection molding cost while still enjoying a premium-quality part that meets your precise requirements. From choosing lower cost materials to considering an overseas facility, read on to explore the unique ways you can save with the right partner on your side.

Lowering Your Injection Molding Cost

Simplify Your Part Design

The more complex your part’s design is, the more expensive it can be to mold. Complex designs may require multiple machines and processes to finalize, and some elements may not be necessary for your part to perform well in its intended application.

To lower your injection molding cost, evaluate which features of your part are the most important for its functionality. It may require specific undercuts or holes to function properly, and these complexities could be prioritized in the part’s design.

On the other hand, some features may be opportunities to simplify the design without impacting the functionality of your part. This can help cut down on the number of tools and amount of time required to finalize your part, which helps reduce your injection molding cost.

Expert Design Aid at Your Service: When you’re ready to lower costs without sacrificing functionality, our design experts are here to help.

Choose the Right Materials

Materials can play a large role in injection molding costs. Some polymers used in injection molding offer unique advantages, from UV resistance and enhanced durability to custom colors and specialized textures. Though these material choices may sound attractive on paper, they can be pricey, and may not be necessary for part performance. Choosing a standard plastic instead of a specialty material can help you save money.

Analyze the requirements for your product based on its intended application. If your product won’t be used in harsh environments like extreme temperatures or chemical applications, a standard resin choice will lower your injection molding cost. Working closely with an experienced injection molder can help you determine what the recommended polymer materials are for your application and how you can keep costs low while still enjoying a high-quality end result.

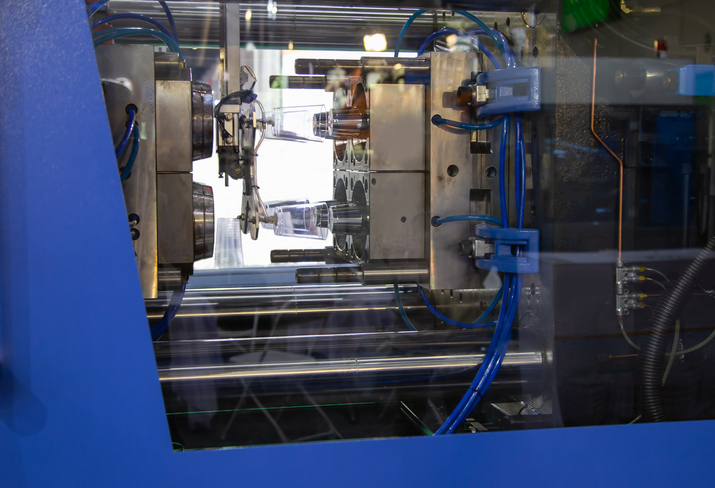

Consider Hollow Parts

Creating a solid part versus a hollow part can be more expensive, and isn’t always necessary for your product’s functionality. Parts that are hollow or have hollow sections lower the amount of resin required for the project, saving you money. Hollowing your part also allows you to run a faster cycle, further reducing costs and speeding up your production process.

When you partner with an expert plastic engineer, you can determine whether designing your part to be hollow will impact its quality or usability. A team of expert engineers and designers can make recommendations for which elements of your part can be more hollow to save money and which features must be solid instead in order for your part to perform as intended.

Choose a Strategic Location

Some injection mold facilities differ in price based on their location. Offshore facilities are known to be lower in cost. Though some individuals worry that offshore facilities won’t deliver premium quality products, when you partner with the right facility, you don’t have to sacrifice quality for cost savings.

At Deluxe, we offer an offshore facility in Vietnam, in addition to our three U.S. locations. Our overseas location is a cost-effective alternative for many companies and ships to the U.S. with ease. In our Vietnam facility, a skilled team operates advanced machinery and produces high-quality products made precisely to your unique specifications.

Whether you choose our Vietnam facility or one of our domestic locations, you can count on a superior experience. Each facility operates with the same exceptional workmanship and commitment to efficient excellence, so no matter which facility you choose, you can enjoy the same premium quality.

Choose a Partner that Cares

The best way to lower your injection molding cost is to partner with a plastic manufacturer that cares about helping you. If your injection molding partner cares about keeping costs fair and timelines low for their customers, their processes will reflect that mission, empowering your project with tools and techniques that can speed up production and save you money.

At Deluxe, we pride ourselves in our efficient practices, and we’ve honed our processes so we can push forward in projects without wasting time. Our 55 injection molding machines operate in three dedicated shifts 24 hours per day and we utilize key automation technology to boost productivity and accuracy. We save our customers money by working swiftly and accurately to stay within your budget and timeline.

We also offer design aid to develop a part design that meets your cost requirements and application specifications, and we offer a range of in-house secondary operations to help you save money and finish out your project as well. From painting to assembly to inventory management, we have the capabilities to carry out your needs with high-quality secondary services. When you partner with us, you can count on our guidance to keep your projects within your unique budget and timeline needs.

Contact Deluxe Plastics to Lower Your Injection Molding Cost Today

At Deluxe Plastics, we’re committed to delivering superior-quality injection molding and unparalleled customer service in a cost-effective manner. We offer a wide range of services to bring your vision to life, from part design and mold building to injection molding, secondary operations, and more. As an ISO 9001:2015 certified company founded nearly a century ago, we’re committed to uncompromising standards of quality and work hard to ensure excellence in everything we do.

From the automotive to medical to industrial sectors and more, Deluxe serves a myriad of industries with high-quality injection molding services. You can count on us to use our expertise and efficient practices to ensure your products are of exceptional quality and always within your budget.

Ready to talk about how to lower your injection molding cost with an expert team? We’re here to help. Contact us today to get started.