A new wave of tariffs is reshaping how American manufacturers think…

When and How to Outsource Your Injection Molding Needs

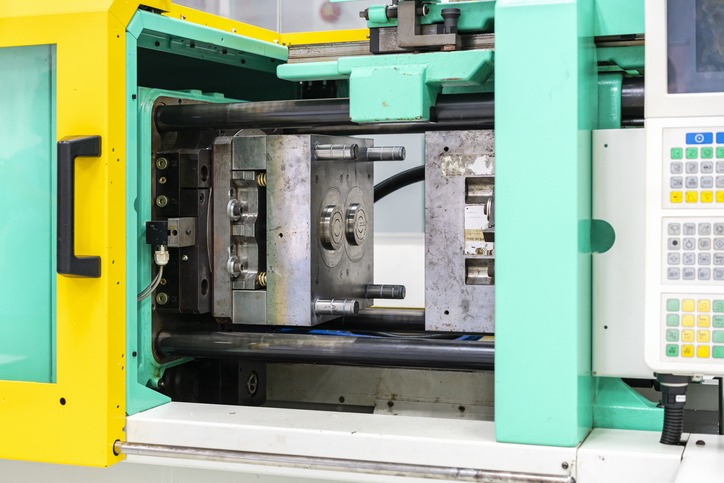

Injection molding is a popular manufacturing process used to produce a variety of parts with wide ranging sizes, properties, and applications. Thermoplastic material is forced into a mold where it cools and then hardens to the mold configurations. Then precision machining is used to form the features of the part you need. Injection molding produces parts for many different industries, including automotive, medical, aerospace, consumer goods, and much more.

Companies that need certain parts should understand the importance of deciding when and how to outsource injection molding needs. Here, we will dive into considerations for contract injection molding, and investigate how to choose the best manufacturing partner for you.

When to Consider Outsourcing Injection Molding

First, when thinking about contract injection molding you should consider costs. Should you invest in expensive new machinery that will create the products you need? Or should you instead pay an outside source to handle it? Think about how much new equipment would cost you versus paying an expert contract partner instead who could take care of the process for you.

Another key consideration is capacity and scalability. What are your ultimate goals with this product? How will you manage inventory to satisfy consumer demand? Outsourcing your injection molding products can help you scale faster and manage fluctuating production volumes.

Finally, consider your core competencies. When selecting whether to outsource your injection molding, it means that you may be able to allocate resources to core business functions. Hiring a contract injection molding partner means you can free up time and resources for other more essential tasks.

Evaluating Potential Injection Molding Partners

Now that you know when you should consider contract injection molding, let’s dive into how to choose the best partner for your specific needs. Here are some key considerations for selecting your injection molding partner:

Assessing Capabilities

First, investigate their capabilities and what services they can provide. Do they offer any other value-added services that could benefit your products? At Deluxe, we offer valuable secondary services, like manual and robotic assembly and inventory management. With our extensive capabilities, we are able to offer start-to-finish support.

In addition, think about what your partner’s experience and expertise is like in your industry. It’s vital that they have valuable knowledge of your specific industry’s needs.

You should also consider your partner’s equipment and available technology. Your contract injection molding partner should be using leading-edge machinery and technology in order to provide you with the very best products. What is the tonnage on their machinery and can it handle the requirements of your products? Deluxe has a wide range of advanced equipment, such as our 55 injection molding machines with tonnage ranging from 20-900 tons. We also have 3 two-shot machines ranging from 600-900 tons, as well as 15 machines equipped with cavity pressure sensing capability. Our high-tech equipment helps us produce outstanding quality products.

Quality Assurance

Next, consider the quality management system of your contract injection molding partner. Investigate their certification standards and quality control processes. For instance, Deluxe Plastics is an ISO 9001:2015 certified company and we have a comprehensive quality management system that is designed to deliver better results for customers. We have various high-tech machinery that inspects each product, including SPC monitoring, moisture analyzer capability, and our Micro-Vu Vertex Vision System with Integrated CMM function. Our design team is dedicated to ensuring your products match your precise needs.

Communication and Support

When choosing your contract injection molding partner, also make sure they provide you with start-to-finish communication and support so you know exactly what is happening with your product at every stage of the process. Responsiveness and excellent customer service are essential for your injection molding partner. At Deluxe, we are dedicated to collaborating with our customers to create parts that exceed expectations. With our start-to-finish support and extensive expertise, our team is prepared to bring your vision to life while keeping you informed throughout every stage of the process.

Partner with Deluxe Plastics for Your Injection Molding Needs

At Deluxe, we are prepared to provide you with high-quality contract injection molding services that meet the needs of your industry. With nearly 100 years of experience as a full-service custom injection molding partner, our team is ready to collaborate with you on whatever best fits your project. Our experience and outstanding customer service speak for themselves. When you’re ready to find your contract injection molding partner, turn to the experts at Deluxe Plastics.