As sustainability continues to shape the future of manufacturing, procurement professionals…

How In-Mold Labeling and In-Mold Decorating Benefit Your Product

In-mold labeling and decorating are methods for adding a label or graphics to a product during the injection molding process. These techniques have influenced product design for decades by elevating products, enhancing the durability and readability of labels, streamlining production processes, and more. In this post, we will explore their benefits and relevance in today’s manufacturing strategies.

In-Mold Labeling and In-Mold Decorating Explained

While in-mold labeling and in-mold decorating share similarities, they are not exactly the same. The difference is primarily the durability of the label or graphic, with in-mold labeling used for products that have a shorter lifespan, like molded containers, and in-mold decorating used for durable goods like appliances, medical equipment, push buttons, and more.

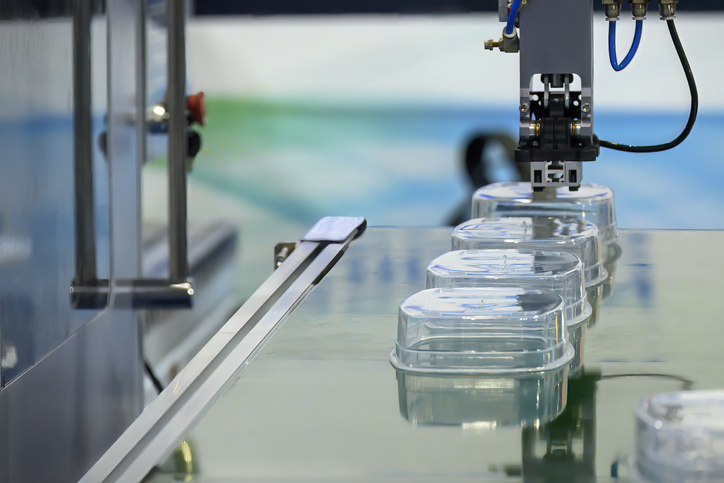

The processes are similar and involve printing a high-quality graphic on a film and precise placement of the label or graphic in the mold. The label of the graphic is held in place with a static charge to prevent movement and to ensure it conforms to the shape of the mold. The plastic injection molding process continues as normal, with the mold closing and plastic being injected into the mold. The injected plastic fuses with the label, creating a wholly integrated design with a smooth finish.

Benefits of In-Mold Labeling and In-Mold Decorating

Whether you have a short-time use or long-use durable product, these labeling and decorating techniques offer benefits over other types of labeling and decorating. Durability, cost-effectiveness, improved aesthetics, and design flexibility are the top reasons manufacturers choose in-mold labeling or decorating.

Durability

One of the biggest draws to these techniques is the label’s or graphics’ durability. Because it is integrated into the product or component, it cannot be separated or removed without destroying the product or component. For durable products with high use and touch, such as push buttons, gear shifts, and appliance knobs, having information or a design that won’t rub off or fade away with time is important to consumers and, in some cases, critical for the proper and safe use of the product.

Durability is equally crucial for limited-use products not only because label design reflects the brand but also because the label may contain important information for products like food, cosmetics, or chemicals. Products exposed to moisture or fluctuations in temperature risk having paper labels smear or tear. This can’t happen with in-mold labeling.

Cost Effectiveness

In-mold labeling and decorating is a cost-effective method for labeling or adding graphics to your plastic product. It is a single-step process that eliminates the need for adhesives and secondary operations. Products can go right from the injection molder to the next stage in manufacturing (e.g., filling, assembly), saving time and creating a more efficient and streamlined production operation. There is also no need to hold an inventory of labels.

Improved Aesthetics and Design Flexibility

Integrated labeling and decorating can elevate your product to a luxury brand status. Brilliant, high-quality graphics with a wide range of colors and textures are possible. Because the label or decoration is placed with robotics, the precision positioning is accurate and repeatable. Detailed graphics and plain text print alike will benefit from crystal clear graphics and legible print provided by these techniques.

In-mold labeling and decorating can accommodate many different shapes, creating flexibility with design. Shapes with recessed panels and asymmetrical features can feature labels that accommodate the design and enhance the product’s aesthetic.

Choose a Trusted Partner For Your In-Mold Labels and In-Mold Decorating

Imagine products that not only stand out but also have a durable and vibrant design that lasts. In-mold labeling and in-mold decorating create a seamless look, resulting in a professional finish that enhances brand recognition and captivates customers. To ensure premium quality, work with a partner you can trust.

At Deluxe Plastics, we understand the importance of part decoration and identification to your brand and customers. In addition to in-mold processes, we also offer a variety of other labeling operations, including pad printing, hot stamping, and custom labeling, giving you the flexibility you need to create the product your customers want. Contact us to request a quote or discuss your project.