A new wave of tariffs is reshaping how American manufacturers think…

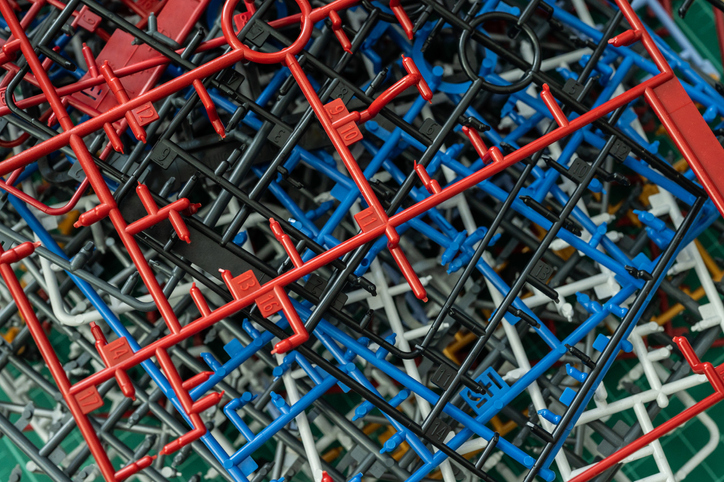

Importance of Optimized Design For Custom Injection Molded Parts

It goes without saying that custom injection molded parts must be designed before they can be molded. However, it is the optimized design that is critical for molding a part that will consistently meet quality and customer specifications. Many molders build to print without providing feedback, and while it can streamline the process, there is a risk that the design may not be optimized, which may cost the customer additional time and money if issues arise and delays occur.

Build to print means the injection molder makes the product based on the drawings provided, which specify the dimensions, tolerances, and materials. The injection molder is responsible for producing the component according to the drawings. While most product manufacturers have capable engineers creating the drawings, sometimes things are missed or assumed. This method heavily relies on clear and accurate communication of design intent, increasing the risk of misinterpretation and potential design flaws. Some engineers may not have experience with specific materials or be familiar with the molder’s presses and manufacturing processes, creating another avenue for issues to arise or opportunities to be lost.

Working with an Injection molder with design expertise will significantly reduce the risk of issues during molding and assembly. The level of design assistance can range from creating a design from the ground up to a review of the customer’s drawings through a design for manufacturability assessment.

Benefits of Working With an Injection Molder for an Optimized Design

Creating an optimized design for the part and the mold offers benefits of increased efficiency, cost reduction and avoidance, and improved quality. An injection molder with design experience will do the following:

- Optimize Part Design and Reduce Costs – The injection molder will provide valuable insights into design optimization, identify potential issues, and suggest solutions that enhance manufacturability, reduce material use, and may even improve part functionality.

- Prevent Defects and Ensure Quality – A comprehensive design review helps identify potential design flaws that could lead to defects during injection molding, such as flow lines, sink marks, warpage, or ejector pin marks. By addressing these issues early in the design phase, the injection molder can minimize the need for costly rework and ensure product quality.

- Optimize Mold Design and Cycle Time – An injection molder who uses mold design tools, such as mold flow analysis, will optimize the mold, leading to shorter cycle times, improved part quality, and reduced scrap rates.

- Enhance Communication and Collaboration – Working with a molder that offers design capabilities fosters open communication and collaboration, enabling the customer to receive expert feedback and make informed design decisions. This collaborative approach can lead to faster time-to-market and a more successful product launch.

Collaborating with an injection molder with design expertise can significantly enhance the entire product development process, from concept to final production. The insights and guidance received by partnering with an experienced injection molder can optimize part and mold designs, leading to increased efficiency, reduced costs, improved quality, and faster time-to-market, as well as ensuring your expectations are met.

How We Optimize Designs to Mitigate Risks

Our team at Deluxe Plastics is comprised of mechanical, electrical, process, and prototype engineers who offer the level of design guidance needed for your project. We are not only looking for issues that can create production challenges, but we are also actively looking for ways to remove costs from your program. Our engineering team has vast knowledge of part design and materials and will collaborate with you to select the best materials for your production, simplify assembly operations, and improve design features.

Design for manufacturability (DFM) and failure mode effect analysis (FMEA) are two methods we use during the product development process to mitigate manufacturability risks. Both processes serve a distinct purpose but work together to ensure the production of high-quality, reliable products.

DFM aligns design and production to reduce costs and ensure efficiency and superior quality. Some considerations that are reviewed include wall thickness, rib and gusset design, gate location, draft angles, boss placement, fillet and radii use, and material selection. Reviewing design characteristics and correcting or improving the design before manufacturing ensures that the design is optimized for production before molds are built. Rebuilding molds after production has started can be costly.

FMEA is a systematic approach for identifying and mitigating potential failure modes in the design and manufacturing process. It helps identify potential areas of risk, like material failure or tooling problems that could lead to product defects. By using DFM principles during the design phase, failure modes can be identified, and FMEA can help to analyze these further to provide a more robust design.

In addition to providing in-depth DFM and FMEA reviews, we use Moldflow® plastic injection molding simulation software to improve plastic part designs, injection mold designs, and manufacturing processes. This software provides a visual map of how the mold will behave and allows us to see how design changes will impact the part.

We are committed to delivering exceptional products that meet our customers’ requirements. Our expertise in DFM and FMEA ensures that potential issues are identified and addressed early in the development process, minimizing production challenges and maximizing cost-effectiveness. With our comprehensive approach and advanced simulation tools, we can confidently guide your project from concept through production, ensuring you can bring your product to market with confidence.

Trust Deluxe Plastics to Deliver

At Deluxe Plastics, we provide end-to-end support for your plastic design and manufacturing needs. Our expert team collaborates with you and, using advanced capabilities, delivers parts that meet your precise specifications, budget, and timeline requirements. By offering part design, mold building, injection molding, and secondary operations under one roof, we strive to be your trusted full-service injection molder.

Contact our team to discuss your custom injection molded parts today.